Onye nrụpụta aka uwe oyi

Njirimara nke usoro ịgha isi oyi

1. A na-eme isi oyi na ụlọ okpomọkụ.Isiokwu oyi nwere ike imeziwanye ihe eji arụ ọrụ nke akụkụ igwe.

2. Usoro ịhịa aka n'ahụ oyi nwere ike ịbawanye ọnụ ahịa ihe onwunwe.Ọ bụ usoro nrụpụta nrụgide dabere na nrụrụ plastik, nke nwere ike ịghọta obere ịkpụ ma ọ bụ enweghị ịkpụ.Ọnụego ojiji ihe n'ozuzu dị na 85% n'elu, nke kachasị elu nwere ike iru 99% n'elu.

3. Nwere ike melite mmepụta arụmọrụ.Metal ngwaahịa deformation oge na usoro bụ dịtụ mkpụmkpụ, karịsịa na multi-ọdụ na-akpụ igwe akụkụ nhazi, nwere ike imeziwanye arụpụtaghị ihe.

4. Nkà na ụzụ na-eme ka oyi na-atụ oyi nwere ike imeziwanye ihe dị elu nke ngwaahịa ma hụ na ngwaahịa ziri ezi.

Chọrọ nke oyi n'isi forging usoro na akụrụngwa

1. Ihe mejupụtara kemịkalụ na akụrụngwa akụrụngwa nke akụrụngwa kwesịrị iru ụkpụrụ dị mkpa.

2. Raw ihe ga-spheroidized annealing ọgwụgwọ, metallographic Ọdịdị nke ihe bụ okirikiri pearlite larịị 4-6.

3. Ihe siri ike nke ihe eji eme ihe, iji belata ihe mgbagwoju anya nke ihe di ka o kwere mee ma meziwanye ndu ndu nke ihe eji eme ihe, a na-acho ihe oyi na-eme ka o nwee ike di ala dika o kwere mee iji meziwanye plasticity.A na-achọkarị isi ike nke akụrụngwa na HB110 ~ 170 (HRB62-88).

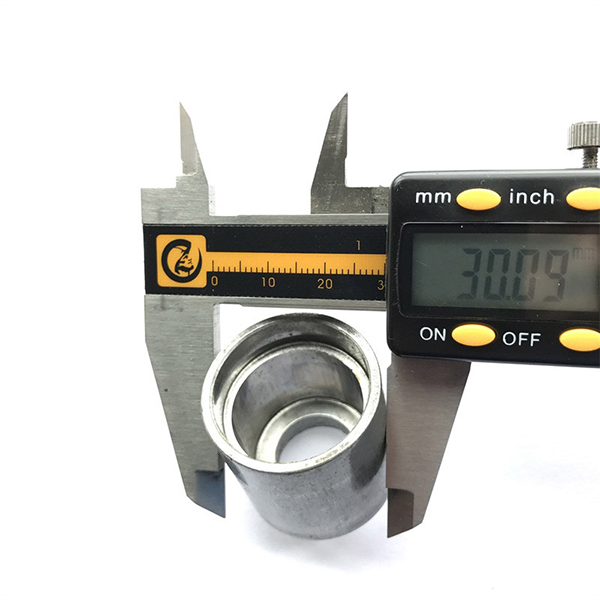

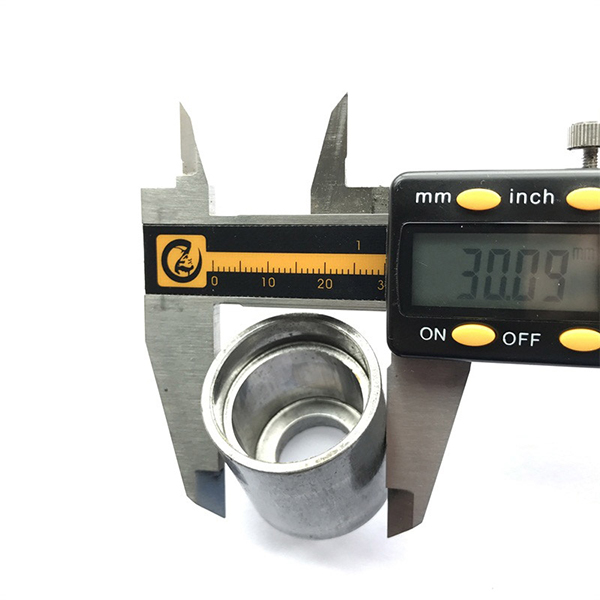

4. Ekwesịrị ikpebi nkenke nke ihe osise oyi dị ka ihe achọrọ nke ngwaahịa na usoro ahụ si dị.N'ikwu okwu n'ozuzu, izi ezi nke

5. Ọdịdị elu nke ihe osise oyi na-achọ ka ihe nkiri na-egbuke egbuke na-agba ọchịchịrị, na elu agaghị enwe ncha, folds, cracks, hair, nchara, oxide skin na olulu pitting na ndị ọzọ ntụpọ.

6. Mkpokọta ọkpụrụkpụ nke decarburization oyi akwa na ntụziaka nke oyi ịbịaru ihe radius ekwesịghị gafere 1-1.5% nke dayameta nke akụrụngwa (ọnọdụ a kapịrị ọnụ dabere na chọrọ nke ọ bụla emeputa).

7. Iji hụ na ịcha mma nke oyi na-akpụ, a na-achọ ihe osise oyi iji nwee elu siri ike na isi ala dị nro.8. Oyi-n'elu forging ule kwesịrị rụrụ maka oyi-adọta ihe, na uche nke ihe na oyi na-arụ ọrụ hardening kwesịrị ịdị ala dị ka o kwere mee, ka ibelata mmụba nke deformation iguzogide n'ihi oyi-arụ ọrụ hardening n'oge. nrụrụ.

Ngosipụta ngwaahịa